- 홈

- >

- 뉴스

- >

- Industry News

- >

- Which industries use magnetic ring encoder products?

Which industries use magnetic ring encoder products?

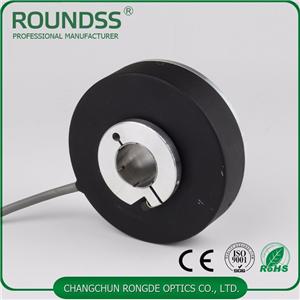

The magnetic ring encoder principle is similar to a photoelectric encoder, but it uses a magnetic field signal. A magnetic turntable and a magnetoresistive sensor are used inside the magnetic encoder. The rotation of the magnetic turntable causes a change in the strength of the internal magnetic field. The magnetoresistive sensor detects the change in the strength of the magnetic field and then outputs a signal through signal processing of the circuit. The number of magnetic poles of the magnetic turntable, the number of magnetoresistive sensors and the way the signal is processed determine the resolution of the magnetic encoder. The advantage of using a magnetic field principle to generate a signal is that the magnetic field signal is not affected by dust, moisture, heat and vibration.

Compared with traditional photoelectric and grating encoders, magnetic ring encoders are more resistant to vibration, corrosion, pollution, interference and wide temperature, and can be applied to fields that traditional photoelectric encoders cannot. Magnetic encoders are encoders designed for extremely harsh environments. These applications generally require wide temperature characteristics to withstand strong vibrations and shocks, and a high degree of protection.

Usually used in metallurgy, paper and woodworking machinery. High-performance magnetic encoders can be widely used in industrial control, machinery manufacturing, shipbuilding, textile, printing, aviation, aerospace, radar, communications, military and other fields.