- 홈

- >

- 뉴스

- >

- Industry News

- >

- What is the use of a rotary encoder in a pipe bender?

What is the use of a rotary encoder in a pipe bender?

Microcomputers, microcontrollers, programmable controllers, advanced AC servo systems, and the application of new hydraulic components and hydraulic technology have made the functions of fully automatic pipe bending machines more perfect. The CNC pipe bending machine will be the main equipment for the production of modern pipe bending.

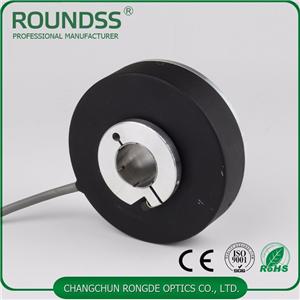

The automatic three-dimensional pipe bending machine control system mainly consists of a programmable controller (PLC), a rotary encoder, a stepping motor, a human machine interface (HMI) and a hydraulic oil pump. Rotary encoder is mainly used for angle measurement and length control. Stepper motor is mainly used for rotation angle control and driving car to realize length control. Solenoid valve is matched with hydraulic oil pump for bending power.

The test machine mode can be selected for the mechanical running-in. The personnel who meet the administrator's authority can select the test machine mode and perform different operations on different users to ensure the system safety. The service life of the machine can be set, and the personnel who meet the administrator's authority can set the service life of the machine; the perfect alarm system can make a prompt on the screen when the operation is improper or mechanical failure, and stop the alarm. It can be divided into manual, semi-automatic, fully automatic and other operation modes, and can meet the specific needs of different control requirements such as single core and multi-core, single angle and multi-angle, two-dimensional angle and three-dimensional angle selection.