- 홈

- >

- 뉴스

- >

- Industry News

- >

- What is a direct drive encoder?

What is a direct drive encoder?

In the conventional drive technology, the motor drives the mechanical equipment through various mechanical devices such as a screw rod, a gear box, a pulley and a coupling to increase the final driving torque. However, mechanical transmissions usually have gaps that inevitably cause positioning deviations. In addition, mechanical wear can cause energy loss, sometimes large noise, and requires regular maintenance.

Direct drive system

In recent years, the trend of direct drive systems has been clearly seen in the field of electric drives. The direct drive system has no mechanical components such as belts or gearboxes, and it has the characteristics of high precision and high reliability, which greatly improves the performance of the equipment.

This makes device manufacturing and integration easier on the one hand, and the cost of maintenance and use is greatly reduced on the other hand.

The use of a direct drive system eliminates the need for complex mechanical transmission components and simplifies the overall mechanical design, making the entire system very compact.

The advantages of the direct drive system are as follows:

1. Longer life without worn parts such as gears and belts

2. Maintenance of less maintenance components such as screwless and gearboxes

3. Higher energy efficiency, no wear and reduce energy loss

4. Faster response without coupling, direct connection

5. Higher precision, almost no backlash

6. Design compact without mechanical transmission components

7. Smooth operation without wear and no noise

Equipment manufacturers may often think that direct-drive motors are costly, but direct drive systems have lower total cost of ownership if they are considered in the long run (such as design, use, and maintenance).

Direct drive motor: The direct drive torque motor is derived from the evolution of synchronous servo motors. It usually has more pole pairs and higher power density, so it has a large output torque at low speeds. It consists mainly of components such as motor housings, windings, permanent magnets, bearings and feedback encoders.

The direct drive linear motor is equivalent to a synchronous servo motor that is cut from the center and is laid flat. The motor stator is composed of permanent magnets, and the rotor is a winding coil connected to the driver.

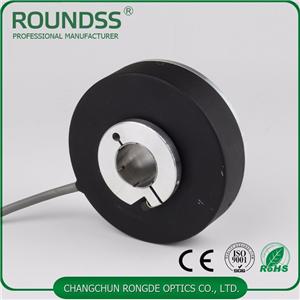

Direct Drive Encoder: As the core feedback component of a direct drive motor, the choice of encoder plays a crucial role in the performance and structure of the entire direct drive system.