- 홈

- >

- 뉴스

- >

- Industry News

- >

- What do you know about the role of the encoder?

What do you know about the role of the encoder?

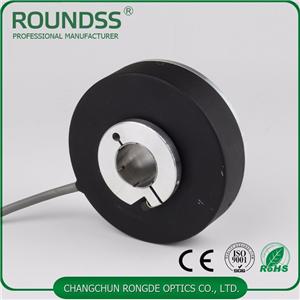

A device in the form of signals for communication, transmission, and storage. The encoder converts an angular displacement or a linear displacement into an electrical signal, the former being called a code wheel and the latter being called a code ruler.

According to the readout mode, the encoder can be divided into contact type and non-contact type; according to the working principle, the encoder can be divided into two types: incremental type and absolute type. The incremental encoder converts the displacement into a periodic electrical signal, which is then converted into a counting pulse, and the number of pulses is used to represent the magnitude of the displacement. Each position of the absolute encoder corresponds to a certain digital code, so its indication is only related to the start and end positions of the measurement, regardless of the intermediate process of the measurement.

First, what is the encoder?

An encoder is a device that converts a change in the physical quantity of a mechanical angle into an electrical signal; in the classification of the sensor, it belongs to an angular displacement sensor. According to this characteristic of the encoder, the encoder is mainly used to measure the angular displacement, angular velocity and angular acceleration of the rotating object. The physical quantity is converted into an electrical signal output to the control system or instrument through the encoder, and the control system or instrument according to these quantities To control the drive.

Second, the role of the encoder

The encoder has a very wide range of encoders to generate electrical signals and is processed by the digital control CNC, programmable logic controller PLC, control system, and the like. These sensors are mainly used in the following areas: machine tools, material processing, motor feedback systems, and measurement and control equipment. The following examples illustrate:

1. The automatic detection of the workpiece by the CNC machine tool is detected by the encoder: the zero calibration of the CNC machine tool holder is also implemented by the encoder.

2, the application of the encoder on the PLC: the general PLC has a high-speed signal input port, the encoder can be used as a high-speed signal input component, enabling the PLC to implement closed-loop control more quickly and accurately. On the inverter, it is usually connected to the PG card of the inverter.

3. The encoder is used on the elevator to measure the lifting speed and position of the elevator.