- 홈

- >

- 뉴스

- >

- Industry News

- >

- What are the specifications for using rotary encoders?

What are the specifications for using rotary encoders?

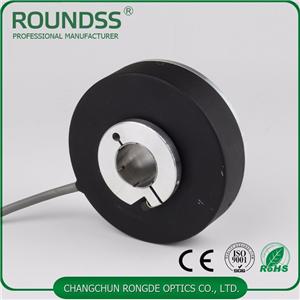

The rotary encoder is a device for measuring the rotational speed and can realize rapid speed regulation in conjunction with PWM technology, and has been widely used in various electronic fields.

The main function of the rotary encoder: the rotary encoder is used to monitor the rotating or rotating parts of the drive system. The rotary encoder is also a sensor that is designed with safety in mind.

In the course of use, the rotary encoder operating procedure is directly related to the safe production. The specifications that the rotary encoder needs to pay attention to in safe operation are as follows:

1. Check if the rotary encoder door is sealed. Five minutes before the work, the ventilation and dust removal equipment must be activated. When the ventilation and dust removal equipment fails, the rotary encoder is prohibited from working.

Second, the rotary encoder should be compatible with the work requirements, generally between the 10th and the 20th.

3. When the rotary encoder is working, it is forbidden for the unrelated personnel to approach. When cleaning and adjusting the operating part, stop it.

4. It is not allowed to use a rotary encoder to compress the air to blow dust.

5. Protective equipment must be worn before work. It is not allowed to operate the rotary encoder with a bare arm.

6. After the work is finished, the rotary encoder ventilation and dust removal equipment should continue to operate for five minutes and then shut down to discharge indoor dust and keep the site clean.