- 홈

- >

- 뉴스

- >

- Industry News

- >

- What are the precautions when installing the incremental draw wire sensor?

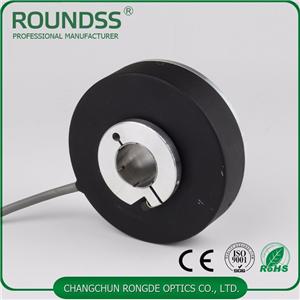

What are the precautions when installing the incremental draw wire sensor?

The choice of resolution, the common calculation method is that the circumference of the inner hub of the rope encoder is divided by the number of pulses of the encoder used and the resolution of the four times is its resolution. In this way, it can be calculated whether the design accuracy is satisfied claim.

Use the incremental draw wire sensor to note the following:

First, the incremental draw wire sensor has a difference in resolution. The linearity of the encoder determines its resolution. The higher the number of pulses, the higher the resolution; this is one of the important basis for selection.

Second, the incremental encoder usually has three signal outputs (differential six signals): A, B and Z, generally adopt TTL level, A pulse is in front, B pulse is in the rear, A and B pulses are 90 degrees apart, each The circle emits a Z pulse that can be used as a reference mechanical zero.

Third, use PLC to collect data, you can use high-speed counting module; use industrial computer to collect data, you can use high-speed counting board; use MCU to collect data, it is recommended to use the input port with optocoupler.

Fourth, it is recommended that the B pulse be a forward (forward) pulse, the A pulse be a reverse (backward) pulse, and the Z origin zero pulse.