- 홈

- >

- 뉴스

- >

- Industry News

- >

- Method for repairing and maintaining a photoelectric pulse encoder

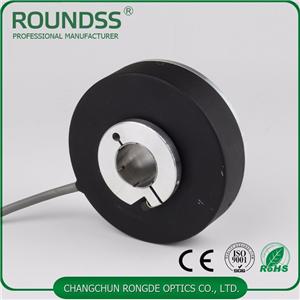

Method for repairing and maintaining a photoelectric pulse encoder

The photoelectric pulse encoder is a gap in which the machine tool has a flat distance on the margin of a disc. The light source and the photosensitive element are separated from the two ends of the machine. When the disc is changed, the light and dark light changes, and the photosensitive element detects the electrical signal. The strength of the weak, then get the pulse signal. The output signals of the encoder are: two phase signal outputs for discriminating; a zero signal (also known as a turn signal) for machine tool reference point control; and other +5v power and ground.

Encoder maintenance and repair:

First, the anti-vibration and anti-fouling encoder is a fine measuring component, its own sealing is excellent, the use environment and disassembly should be the same as the grating ruler to prevent vibration and anti-fouling. The pollution is simple to appear in the lead-out section of the wire, and the plug is connected to protect the parts. The machine tool oscillates simply to form an internal fastener that loosens and falls, forming an internal short circuit.

Second, the connection of doubts connected questions are divided into loose connection and adjustment of the connection is not appropriate. Encoder connection methods are built-in and external. Machine tool built-in and servo motor coaxial device, such as Siemens 1F75, IFr6 servo motor ROD320 encoder; external device at the end of the drive chain, when the drive chain is long, this device method can reduce the accumulation of j chain The effect of errors on the accuracy of the orientation detection. Because the machine tool is loose, it often affects the azimuth control accuracy. In addition, in some communication servo motor built-in encoders in addition to the orientation detection, together with the speed measurement and communication servo motor rotor orientation detection effect, therefore, the encoder (electronic handwheel) connection loosening will also lead to the feed movement Stable, affecting the commutation control of the communication servo motor, and then causing the machine to oscillate. In addition, the encoder is connected by the belt drive. If the belt is too tightly adjusted, the encoder bearing force is applied too much, and the encoder is simply damaged.

Changchun Rongde Optical Co., Ltd. is a high-tech enterprise integrating R&D, manufacturing and sales of industrial encoders and high-precision couplings. The company's main products include encoders and couplings, and wire-type displacement sensors.