- 홈

- >

- 뉴스

- >

- Industry News

- >

- How to install a rotary encoder product?

How to install a rotary encoder product?

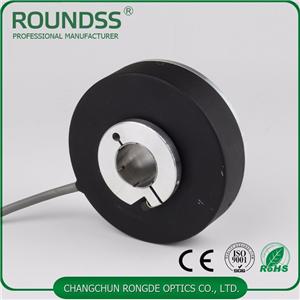

Rotary encoder is a kind of precision measuring angular displacement sensor based on the principle of electromagnetic induction. It can be used to measure the rotational speed of mechanical devices. It can also adjust the speed of mechanical devices. Sometimes the speed of machining needs to be changed to use rotary encoders. Come to work. Rongde Optics introduces how to install rotary encoder products?

The commonly used rotary encoder has 5 leads, 3 of which are pulse output lines, 1 is a COM end line, and 1 is a power line (OC gate output type). The power supply can be an external power supply or a PLC power supply. The "-" end of the power supply should be connected to the COM end of the encoder, and the "+" should be connected to the power supply end of the encoder. The COM end of the encoder is connected to the COM input terminal of the PLC. The A, B and Z two-phase pulse output lines are directly connected to the input end of the PLC. A and B are pulses with a difference of 90 degrees. The rotary encoder also has a shielded wire. When used, the shielded wire should be grounded to improve the anti-interference.

Rotary encoder installation steps and installation precautions

1. Please be sure to install the encoder firmly to avoid loosening caused by vibration;

2. When the shaft of the encoder is coupled to the shaft of the machine through the coupling, make sure there is no deviation;

3. When the shaft of the encoder is coupled to the machine shaft, make sure that the load of the shaft cannot exceed its maximum allowable value;

4. Do not connect with a rigid coupling;

5. Please tighten the screws of the coupling to avoid loosening during use;

6. Please choose the appropriate coupling, because the weight of the coupling also increases the load of the shaft;

7. When using a conveyor belt, please use the timing belt, otherwise the angle of transmission is not accurate;

8. When using a timing belt, make sure the belt tension is appropriate. Please pay attention to belt installation and looseness during use;

9. Please avoid the vibration and deviation of the pulley caused by the radial load during the rotation;

10. When the shaft of the encoder and the shaft of the machine are coupled by gears, please avoid partial or whole vibration of the gear caused by radial load;

11. Please do not hit the encoder through the coupling, belt and gear;

12. The coupling vibration of the shaft should be controlled at 0.1T.I.R.