- 홈

- >

- 뉴스

- >

- Industry News

- >

- How to choose the encoder product on the peel strength tester?

How to choose the encoder product on the peel strength tester?

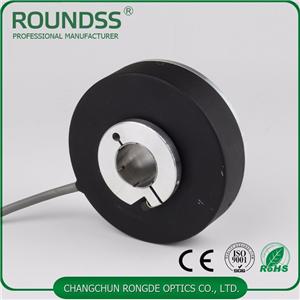

The peel strength tester is also a tensile machine. First of all, it is necessary to know where the encoder is used. Usually, the encoder on the electronic tension machine is an extension effect on the test sample. It has many kinds of names and is usually used in electronics. On the tension machine, it is not a rotary type or a square type. The rotary circular photoelectric encoder is widely used in various industrial systems because it has only one orientation, anti-interference and no need to lose power. Viewpoint, length test and positioning control. If you want to measure the rotation beyond 360 degrees, you need to use a multi-turn positive encoder.

The encoder manufacturer uses the principle of the wall clock gear machine. When the center code wheel rotates, another set of code wheels (or sets of gears, multiple sets of code disks) is driven by the gear, and the number of turns is added on the basis of the single circle code. Encoding to extend the measurement scale of the encoder, such a positive encoder is called a multi-turn positive encoder, which is also coded by mechanical orientation, and each orientation code is only non-repetitive, without recall.

The rotary encoder on the electronic tension machine has high test accuracy, good recovery performance, long service life, 360 degree without any disturbance signal, the uniqueness of each orientation, it does not need to recall, no need to find a reference point, and You don't have to count all the time, when you need to know the direction, and when to read its position.

The anti-interference characteristics of the encoder and the reliability of the data are greatly improved. Another advantage of multi-turn encoders is that because of the large scale of measurement, the actual use is often more expensive, so it is not necessary to find a zero point in the device, and a certain center position can be used as a starting point, which greatly simplifies the difficulty of device debugging.

Multi-turn positive encoders have significant advantages in length positioning and are now increasingly used in industrial control positioning.