- 홈

- >

- 뉴스

- >

- Industry News

- >

- How to choose and install variable frequency motor encoder

How to choose and install variable frequency motor encoder

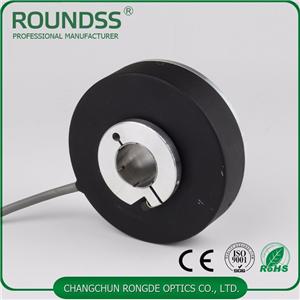

A rotary encoder is a device for measuring the rotational speed. It is divided into single output and dual output. Variable frequency motor control speed regulation, if feedback signal is needed, it is generally equipped with encoder. Most of the encoder uses pulse signal, and the receiving interface of the inverter controller, in fact, the speed feedback encoder has pulse signal, Many kinds are available. Rongde Optics introduces the precautions for selecting and installing the inverter motor encoder:

First, oscillation

Oscillation applied to a rotary encoder (encoder selection) tends to be the cause of a false pulse episode. Therefore, pay attention to the installation location and installation location. The more the number of pulses per forward, the narrower the slot spacing of the rotating slot disk, and the more susceptible it is to oscillation. At low speeds of rotation or abort, the oscillations applied to the shaft or body cause the rotating disk to vibrate and may cause false pulses.

Second, the device

Do not apply a direct impact to the shaft when installing the unit. A flexible adapter should be used to connect the encoder shaft to the machine. When installing the adapter on the shaft, do not press it in hard. Even if the adapter is used, it is possible to add a load to the shaft that is greater than the allowable load due to the poor installation, or to form a core, so pay special attention. The bearing life is related to the operating conditions and is particularly affected by the bearing load. If the bearing load is smaller than the regular load, the bearing life can be greatly extended. Do not disassemble the rotary encoder. This will damage the oil and drip prevention features. Anti-drip products should not be immersed in water or oil for a long time, and should be scrubbed and cleaned when there is water or oil on the outside.

Third, about wiring and convergence

Incorrect wiring may damage the internal circuit, so pay attention to the wiring:

1. Wiring should be performed while the power is off. When the power is turned on, if the output line touches the power supply, the output circuit may be damaged.

2. If it is connected in parallel with the high-voltage line or the power line, it may be damaged by induction, and it may be separated from the wiring.

3. If the wiring is faulty, the internal circuit may be damaged. Therefore, pay attention to the polarity of the power supply during wiring.

4. In order to prevent induced noise, etc., try to use the shortest interval wiring. When inputting to an integrated circuit, special attention is required.

5. When extending the wire, it should be below 10m. Moreover, because of the spreading capacity of the wires, the rise and fall times of the waveforms are long. When in doubt, the waveforms are shaped using a Schmidt circuit.

6. When the wire is extended, the rise and fall times of the waveform are lengthened due to the influence of the conductor resistance and the capacitance between the wires, and the disturbance between the signals (crosstalk) is simply caused, so that a wire having a small resistance and a low capacitance between the wires (twisted pair) is used. , shielded wire).