- 홈

- >

- 뉴스

- >

- Industry News

- >

- How to choose an encoder product in different environments?

How to choose an encoder product in different environments?

Many encoders are optical. The internal signal reading of the encoder of the optical system needs to be aligned with the code channel and the engraved line. In the vibrating environment, it is easy to scribe the line and the data is jittered or erroneous, which causes the subsequent reading device. The value is wrong, and some are easily damaged by the vibration of the glass code disc. The magnetoelectric absolute encoder is an inductive quadrature differential canceler, which eliminates the distance and small change of position caused by vibration, so it is not sensitive to vibration and does not cause data jump error. At the same time, the magnetoelectric encoder does not have an optical system glass code disc and is not easily damaged. Therefore, in a vibrating environment, it is recommended to select a magnetoelectric absolute encoder. The magnetoelectric absolute encoder is relatively low in accuracy, but the basic accuracy is not high in the case of large vibration. Therefore, the disadvantage of the lower accuracy of the magnetoelectric absolute encoder is not affected. It is recommended to select a magnetoelectric absolute encoder.

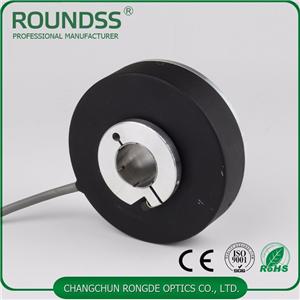

The stainless steel housing has a one-time screw-free encoder, which is not only highly reliable with IP protection, but also has high corrosion resistance, impact resistance and high vibration resistance. Especially in coastal applications, it is required to resist sea breeze. In the use of mining machinery, it is required to use magnesium-aluminum light metal materials as the outer casing; it is convenient for water gun washing on large and heavy equipment with poor dust environment, and it is easy to clean and disinfect on food and medical packaging.

On the other hand, the encoder that is packaged once in the stainless steel case is difficult to disassemble and repair, and the reliability of the internal device is required to be high, not easy to be broken, and the maintenance rate is low. Reduce the downtime maintenance from the long-term use of the encoder, which can greatly save the user's use cost and after-sales service cost. It is recommended to choose an encoder in a stainless steel housing.