- 홈

- >

- 뉴스

- >

- Industry News

- >

- High resolution incremental encoder supply

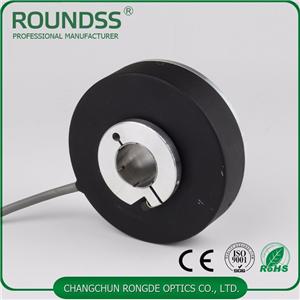

High resolution incremental encoder supply

As an important part of the transmission control, the detection device detects the displacement and sends a feedback signal to compare with the command signal from the control device. If there is a deviation, the control unit is controlled to move in the direction of eliminating the deviation. Until the deviation is equal to zero. In order to improve the machining accuracy of the mechanical device, it is necessary to improve the accuracy of the detecting element and the detecting system. Among them, rotary encoders, linear encoders (grating scales, magnetic scales), rotary transformers, tachogenerators, etc. are common, among which encoders are one of the most commonly used detection devices for various types of machinery, using encoders as signal detection. The method has been widely used in the fields of numerical control machine tools, textile machinery, metallurgical machinery, petroleum machinery, mining machinery, printing and packaging machinery, plastic machinery, testing machines, elevators, servo motors, aviation, instrumentation and other industrial automation fields. There are many kinds of encoders, and the parameters and specifications of the encoders are different for different industry users. The encoder is divided by readout, both contact and non-contact. The contact type uses a brush output, and the brush contacts the conductive area or the insulating area to indicate whether the state of the code is "1" or "0"; the non-contact receiving sensitive element is a photosensitive element or a magnetic sensitive element, and the photosensitive element is used to pass through The light zone and the opaque zone indicate whether the state of the code is "1" or "0". The encoder is divided into detection methods, including optical, magnetic, inductive and capacitive. The encoder is divided by measurement, with linear encoder (linear scale, magnetic scale), rotary encoder