- 홈

- >

- 뉴스

- >

- Industry News

- >

- CNC machine tool industry

CNC machine tool industry

In the CNC machine tools, the AC servo motor bed table is mainly used for motion control. In order to display or control the displacement of the machine table, it is often necessary to convert it into a digital quantity. For this purpose, a position sensor is required, which is commonly used with a code wheel, an inductive synchronizer, a synchronous machine and a grating. CNC machine tools generally use a code wheel and a grating (hereinafter referred to as an encoder) for position detection.

The encoder has two kinds of absolute encoders and value-added encoders. In the position detection of CNC machine tools, it is desirable to give the relative displacement of the table. In this case, an incremental value sensor is required.

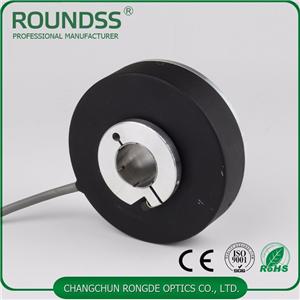

The incremental encoder consists of an incremental value sensor and a signal processing circuit for detecting the relative displacement of the table in a numerically controlled machine tool system.

Incremental sensor, an incremental value code disc is an example. It is an optical code disc. The coding pattern consists of a series of radial transparent slits of equal spacing, which are used to obtain two precision optical slits. 1/4 pitch. The incremental encoder directly uses the optical conversion principle to output three sets of square wave pulses A, B and Z phases; the phase difference between the two groups A and B is 90·, so that the direction of rotation can be conveniently determined, and the Z phase is per revolution. A pulse for reference point positioning. Its advantage is that the principle structure is simple, the average mechanical life can be more than tens of thousands of hours, the anti-interference ability is strong, the reliability is strong, and it is suitable for long-distance transmission. The disadvantage is that the absolute position information of the shaft rotation cannot be output.