- 홈

- >

- 뉴스

- >

- Industry News

- >

- Application of rotary encoder in servo motor field

Application of rotary encoder in servo motor field

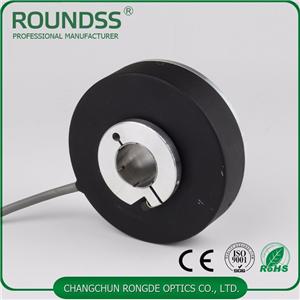

I believe that engineers who do mechanical equipment know that servo motors, stepper motors and brushless motors are the most common types of precision mechatronic motors. All of these motors have a common feature: they all give numbers to the drive. Signal to the motor to operate the motor in the established mode. Controllable, programmable and high precision are the main features of these motors. However, some customers' equipment needs precise positioning, such as accurate positioning of the speed, precise positioning of the displacement, etc., which cannot be realized by the motor and the drive alone. At this time, you need to install an encoder.

The servo motor encoder is a high precision electromechanical component that monitors and feeds the direction and position of the motor. If you want to achieve basic synchronization between servo and inverter, you need a control interface to control

The rotor inside the servo motor is a permanent magnet. The U/V/W three-phase electric motor controlled by the driver forms an electromagnetic field. The rotor rotates under the action of the magnetic field. At the same time, the encoder feedback signal from the motor is supplied to the driver. The driver according to the feedback value and target. The values are compared to adjust the angle at which the rotor rotates. The accuracy of the servo motor is determined by the accuracy (number of lines) of the encoder.